[Peak Oil] Addiction to Oil countered by... Grass

Moderator: Alyrium Denryle

- Admiral Valdemar

- Outside Context Problem

- Posts: 31572

- Joined: 2002-07-04 07:17pm

- Location: UK

I always assume that cellulose sources would be from the wastes of agriculture, such as leaves, stems and thrown out foodstuffs. That way you're simply making the system more efficient, rather than, as we're doing now, drive up food prices to protest levels by chucking corn, soya and rapeseed into your fuel tank.

- K. A. Pital

- Glamorous Commie

- Posts: 20813

- Joined: 2003-02-26 11:39am

- Location: Elysium

Of course. That's what bugs me.That way you're simply making the system more efficient, rather than, as we're doing now, drive up food prices to protest levels by chucking corn, soya and rapeseed into your fuel tank.

Our milk and bread prices have jumped 50% since early august and I heard that American milk price is up 80%.

This situation will cause food production contraction and then hunger in the Third World. Forced to compete with oil demands, Third World countries will no doubt increase hostility to those who use up agricultural produce for fuel when people starve.

Lì ci sono chiese, macerie, moschee e questure, lì frontiere, prezzi inaccessibile e freddure

Lì paludi, minacce, cecchini coi fucili, documenti, file notturne e clandestini

Qui incontri, lotte, passi sincronizzati, colori, capannelli non autorizzati,

Uccelli migratori, reti, informazioni, piazze di Tutti i like pazze di passioni...

...La tranquillità è importante ma la libertà è tutto!

Lì paludi, minacce, cecchini coi fucili, documenti, file notturne e clandestini

Qui incontri, lotte, passi sincronizzati, colori, capannelli non autorizzati,

Uccelli migratori, reti, informazioni, piazze di Tutti i like pazze di passioni...

...La tranquillità è importante ma la libertà è tutto!

Assalti Frontali

- Fingolfin_Noldor

- Emperor's Hand

- Posts: 11834

- Joined: 2006-05-15 10:36am

- Location: At the Helm of the HAB Star Dreadnaught Star Fist

Never mind that. Mexico's bigger problem is its oil fields are drying up![R_H] wrote:Wasn't there a huge problem in Mexico with the tortilla prices going up because of the increased demand for biofuels?

Your spirit, diseased as it is, refuses to allow you to give up, no matter what threats you face... and whatever wreckage you leave behind you.

Kreia

- Admiral Valdemar

- Outside Context Problem

- Posts: 31572

- Joined: 2002-07-04 07:17pm

- Location: UK

- Gil Hamilton

- Tipsy Space Birdie

- Posts: 12962

- Joined: 2002-07-04 05:47pm

- Contact:

Actually, I thought I said that. The mechanism for eating cellulose is there, in nature, we just need to make it better. My point is that cellulose ethanol isn't inventing the wheel, it's making a better wheel. It can be done, even if it takes another Manhattan project to do it.Admiral Valdemar wrote:Gil, it's not really the technical issue of breaking down cellulose, which we all know is quite doable given every herbivore on Earth does it daily. The issue is with making this work on and industrial scale, for our daily liquid fuel use and that is somewhere this side of financially viable. The Law of Receding Horizons tends to mean that, as with heavy oil like tar sands and shale or deep-water sources, the price rises of conventional crude don't make these unconventional sources more viable. Instead, they suffer higher costs as a result of increased energy prices across the board.

So while I can see it being done on some scale if necessary, I can't say I see it replacing what we use now in crude and not killing the global economy in the process. Of course, the alternatives are all this difficult to choose from and inaction would be a death knell more so than going to wrong route, but life sucks that way.

Gasification is easier though still suffers the same problems. At least some Scandinavian countries used this system to great effect decades ago.

Of course, it will be hard and involve some chances. Personally, I'd try and go at with with ethanol/electric hybrids and pure BEVs, powered mostly by nuclear and cellulose ethanol sources, supplemented locally by renewable resources where their efficient (geothermal in some parts of Utah, wind power in the Appalachians, hydro dams, temperature differential off of Florida, that sort of thing). We'll have to tighten our belts, but as you've noted on many occasions, our lifestyles are too fat anyway, and losing the weight could be very good for us once everything settles out.

This is why I've been pushing kudzu. It's PACKED with cellulose and the best part is that where it is by far the richest in cellulose is non-edible anyway (the vines). You can eat the leaves and shoots like spinach and have the vines for a fuel source. Better yet, it's as close to no input a crop as you can get... the trick is not letting it take over (the American south is covered in the stuff because of this)!Stas Bush wrote:Do people think about mass conversion of foodstoffs for energy, and what effect that would have on the world food supply situation?

It's alot better than corn which is environmentally abysmal and strongly tied to food prices.

"Show me an angel and I will paint you one." - Gustav Courbet

"Quetzalcoatl, plumed serpent of the Aztecs... you are a pussy." - Stephen Colbert

"Really, I'm jealous of how much smarter than me he is. I'm not an expert on anything and he's an expert on things he knows nothing about." - Me, concerning a bullshitter

"Quetzalcoatl, plumed serpent of the Aztecs... you are a pussy." - Stephen Colbert

"Really, I'm jealous of how much smarter than me he is. I'm not an expert on anything and he's an expert on things he knows nothing about." - Me, concerning a bullshitter

-

Kanastrous

- Sith Acolyte

- Posts: 6464

- Joined: 2007-09-14 11:46pm

- Location: SoCal

The Air Force built experimental fission-powered ramjet propulsion systems in the 1950s and 1960s as part of the 'Flying Crowbar' program.kinnison wrote: The solution may be in your sig - the only actual reason for carrying fuel around for a jet engine is as a source of heat, which is a very different situation from space applications. The air going through the engine is the reaction mass. If you have a working fusion reactor of reasonably small size, you can then heat said air using fusion energy, probably in the form of electrical heating - perhaps a plasma discharge within the engine, but I'm no expert. (Is anyone, on this subject?)

They obtained results, although the horrifying deadly radioactive exhaust was a persistent drawback to the design.

Don't see why the same thing shouldn't work and give a clean exhaust jet, if you could substitute a small fusion-powered heat source, for the fission pile the Crowbar was intended to use.

I find myself endlessly fascinated by your career - Stark, in a fit of Nerd-Validation, November 3, 2011

- Admiral Valdemar

- Outside Context Problem

- Posts: 31572

- Joined: 2002-07-04 07:17pm

- Location: UK

I know you did, that's why the "as we all know" is there.Gil Hamilton wrote: Actually, I thought I said that.

That's just it though. The technical kinks are actually less of a problem, in fact, they are for most alternatives. The willpower is lacking, and for that we need a paradigm shift equal to what made us move to suburban life as it is. People do not like change, more so when it could mean being less well off.The mechanism for eating cellulose is there, in nature, we just need to make it better. My point is that cellulose ethanol isn't inventing the wheel, it's making a better wheel. It can be done, even if it takes another Manhattan project to do it.

Of course, it will be hard and involve some chances. Personally, I'd try and go at with with ethanol/electric hybrids and pure BEVs, powered mostly by nuclear and cellulose ethanol sources, supplemented locally by renewable resources where their efficient (geothermal in some parts of Utah, wind power in the Appalachians, hydro dams, temperature differential off of Florida, that sort of thing). We'll have to tighten our belts, but as you've noted on many occasions, our lifestyles are too fat anyway, and losing the weight could be very good for us once everything settles out.

-

kinnison

- Padawan Learner

- Posts: 298

- Joined: 2006-12-04 05:38am

Part of the point is that quite a lot of prospective fuel plants can grow in places where common food plants would take extreme measures to grow - semi-desert and/or poor soil areas. One example of this is the obscure (getting less so!) plant jatropha. Link:

http://www.reuk.co.uk/What-is-Jatropha.htm

http://www.reuk.co.uk/What-is-Jatropha.htm

- drachefly

- Jedi Master

- Posts: 1323

- Joined: 2004-10-13 12:24pm

1) small fusion-powered heat source is roughly in the same category as a space elevator in terms of accessibility. Maybe worse.Kanastrous wrote:Don't see why the same thing shouldn't work and give a clean exhaust jet, if you could substitute a small fusion-powered heat source, for the fission pile the Crowbar was intended to use.

2) fusion isn't exactly free of radiation. Like, not at all.

- Beowulf

- The Patrician

- Posts: 10621

- Joined: 2002-07-04 01:18am

- Location: 32ULV

Most commercially viable fusion reactions emit either protons or neutrons, not penetrating gamma radiation. It's not free of radiation, but they can be shielded against fairly well. The reactor vessel would admittedly become radioactive, as well as suffer neutron embrittlement.drachefly wrote:2) fusion isn't exactly free of radiation. Like, not at all.

In any case, a fusion reactor would be much nicer than a fission reactor for a Flying Crowbar type design.

"preemptive killing of cops might not be such a bad idea from a personal saftey[sic] standpoint..." --Keevan Colton

"There's a word for bias you can't see: Yours." -- William Saletan

"There's a word for bias you can't see: Yours." -- William Saletan

- drachefly

- Jedi Master

- Posts: 1323

- Joined: 2004-10-13 12:24pm

Neutrons can be shielded against nicely?

I was so surprised by this, after not finding anything convenient via google (it is/i] fast), I went upstairs to the ATLAS group and looked at their posters. One of the profs asked if he could help me, and I asked him, in either particle accelerator or fusion reactor context, whether neutrons were at all easy to stop, esp. in comparison to gammas.

The answer was exactly what I expected: Gammas are stopped pretty much immediately, even the insanely high energy ones they're looking at in a particle accelerator context (much higher energy than in a fusion reactor). Neutrons go a lot further. Another professor who overheard said that neutrons were the only thing (besides neutrinos) that gets out of fusion reactors at all.

And a flying fusion reactor is going to be lighter and less shielded than a ground-based one.

So there's going to be neutron radiation.

And neutron radiation is especially pernicious, since it makes many common kinds of matter itself radioactive. It's not just an issue of embrittlement.

I was so surprised by this, after not finding anything convenient via google (it is/i] fast), I went upstairs to the ATLAS group and looked at their posters. One of the profs asked if he could help me, and I asked him, in either particle accelerator or fusion reactor context, whether neutrons were at all easy to stop, esp. in comparison to gammas.

The answer was exactly what I expected: Gammas are stopped pretty much immediately, even the insanely high energy ones they're looking at in a particle accelerator context (much higher energy than in a fusion reactor). Neutrons go a lot further. Another professor who overheard said that neutrons were the only thing (besides neutrinos) that gets out of fusion reactors at all.

And a flying fusion reactor is going to be lighter and less shielded than a ground-based one.

So there's going to be neutron radiation.

And neutron radiation is especially pernicious, since it makes many common kinds of matter itself radioactive. It's not just an issue of embrittlement.

-

Kanastrous

- Sith Acolyte

- Posts: 6464

- Joined: 2007-09-14 11:46pm

- Location: SoCal

1) Sure. So's biomass-replacement of fossil fuels, for our energy needs, at the moment.drachefly wrote:

1) small fusion-powered heat source is roughly in the same category as a space elevator in terms of accessibility. Maybe worse.

2) fusion isn't exactly free of radiation. Like, not at all.

2) I was imagining a fusion motor that keeps the fusing plasma contained (doesn't one have to keep it contained?) and runs air through or around the containment vessel (unlike the Pluto engines that just shot air straight through the fission pile, and out the back).

Not being an engineer, I can happily imagine all sorts of unlikely stuff...

I find myself endlessly fascinated by your career - Stark, in a fit of Nerd-Validation, November 3, 2011

- Sikon

- Jedi Knight

- Posts: 705

- Joined: 2006-10-08 01:22am

Though cellulosic ethanol was discussed a bit before, here's some to add on recent progress, beyond the info in the opening post article which is good but incomplete:

Cellulosic ethanol plants are starting to get some funding, such as $2 billion from the USDA announced earlier this year, to support working towards a goal of 20 billion gallons per year by 2017. (U.S. gasoline consumption today is a total of 140 billion gallons a year). It's a limited amount of funding really, out of $130000+ billion GDP per decade. There should have been more of a switch away from oil long before. But at least this is something. The goal is not to pay all the expense of production plants but just to subsidize enough to make them competitive in the marketplace.

As a random example, just several months ago, Range Fuels applied for a permit for a 100 million gallon/yr cellulosic ethanol plant in Georgia. With construction currently proceeding, some production from it will begin next year (2008).

The opening post article focuses on enzymatic conversion of cellulosic ethanol. Such does have potential for cost breakthroughs that might make it most inexpensive in the future. However, such a biologically inspired method is more of a research challenge than inorganic, abiotic thermochemical conversion. Thermochemical conversion is slightly analogous to how Germany in WWII converted coal to synthesis gas to produce gasoline, albeit with different reactions and different starting versus final products:

biomass + heat/pressure/steam -> reactor with catalyst -> alcohol

instead of

coal + partial-combustion/heat/pressure/steam -> reactor with catalyst -> non-alcohol hydrocarbons

Diverting a portion of the waste lignin allows enough energy to fuel the process.

Range Fuel's technique is to convert the biomass into synthesis gas with heat, pressure, and steam, then the plant converts the hot syngas to alcohols by passing it over a catalyst.

From here.One company wrote:Verenium is a leader in process technology for cellulosic ethanol -- a clean-burning fuel derived from biological feedstocks (such as canes, grasses, hardwoods and softwoods) that are readily available outside the food chain.

[...]

Under an exclusive license with Verenium covering four nations in East Asia, Marubeni Corporation and Tsukishima Kikai Corporation, LTD (TSK) completed the first demonstration project using the Company’s technology in January 2007 [a plant which is currently producing cellulosic ethanol].

[...]

A second phase, planned for completion in 2008, will increase production to 4 million liters per year.

Cellulosic ethanol plants are starting to get some funding, such as $2 billion from the USDA announced earlier this year, to support working towards a goal of 20 billion gallons per year by 2017. (U.S. gasoline consumption today is a total of 140 billion gallons a year). It's a limited amount of funding really, out of $130000+ billion GDP per decade. There should have been more of a switch away from oil long before. But at least this is something. The goal is not to pay all the expense of production plants but just to subsidize enough to make them competitive in the marketplace.

As a random example, just several months ago, Range Fuels applied for a permit for a 100 million gallon/yr cellulosic ethanol plant in Georgia. With construction currently proceeding, some production from it will begin next year (2008).

The opening post article focuses on enzymatic conversion of cellulosic ethanol. Such does have potential for cost breakthroughs that might make it most inexpensive in the future. However, such a biologically inspired method is more of a research challenge than inorganic, abiotic thermochemical conversion. Thermochemical conversion is slightly analogous to how Germany in WWII converted coal to synthesis gas to produce gasoline, albeit with different reactions and different starting versus final products:

biomass + heat/pressure/steam -> reactor with catalyst -> alcohol

instead of

coal + partial-combustion/heat/pressure/steam -> reactor with catalyst -> non-alcohol hydrocarbons

Diverting a portion of the waste lignin allows enough energy to fuel the process.

Range Fuel's technique is to convert the biomass into synthesis gas with heat, pressure, and steam, then the plant converts the hot syngas to alcohols by passing it over a catalyst.

- Admiral Valdemar

- Outside Context Problem

- Posts: 31572

- Joined: 2002-07-04 07:17pm

- Location: UK

At the moment, it's probably cheaper to burn the dollars for fuel, rather than go with ethanol plants. The start-up and operating costs are far too high for a plant to supply any meaningful amount of replacement liquids for oil.

I'd rather they just went with burning the organic matter and producing electricity for an electrified network worth its weight, as opposed to going through this highly expensive in both money and energy process of making ethanol viable.

I'd rather they just went with burning the organic matter and producing electricity for an electrified network worth its weight, as opposed to going through this highly expensive in both money and energy process of making ethanol viable.

- Illuminatus Primus

- All Seeing Eye

- Posts: 15774

- Joined: 2002-10-12 02:52pm

- Location: Gainesville, Florida, USA

- Contact:

I'm with Valdemar. Organic cellulosic ethanol production would be nice to allow us to reclaim waste from farming and other petrochemical sinks (ditto for thermal depolymerization). But its really too late and it'd be better to go with limited EV technology where you must (combines etc.) and go back to electrified light and heavy rail for most everything else.

"You know what the problem with Hollywood is. They make shit. Unbelievable. Unremarkable. Shit." - Gabriel Shear, Swordfish

"This statement, in its utterly clueless hubristic stupidity, cannot be improved upon. I merely quote it in admiration of its perfection." - Garibaldi in reply to an incredibly stupid post.

The Fifth Illuminatus Primus | Warsie | Skeptical Empiricist | Florida Gator | Sustainability Advocate | Libertarian Socialist |

"This statement, in its utterly clueless hubristic stupidity, cannot be improved upon. I merely quote it in admiration of its perfection." - Garibaldi in reply to an incredibly stupid post.

The Fifth Illuminatus Primus | Warsie | Skeptical Empiricist | Florida Gator | Sustainability Advocate | Libertarian Socialist |

- Zixinus

- Emperor's Hand

- Posts: 6663

- Joined: 2007-06-19 12:48pm

- Location: In Seth the Blitzspear

- Contact:

(pre-note: sorry for the misspellings and typos, but its late for me)

If we cut off the option of biofuels/hydrogen/whatever away then the public will be stuck with the other option of regular oil. People have cars, and a deal of them need cars, and a good lot more of them DEMAND cars.

The idea of supporting mass transportaion more is a sane and logical one. However, it meets a dead stop at cultural imperative. People want cars, people need cars and cars need fuel. Politics will move towards this, whoever promises avalability of fuel to the public will get elected.

That said, public transportation, especially trains that are a simple yet still highly efficient, has to be developed. With some sanity, governments will try to do that as well as to balance fuel production.

And the Prof is very right. Neutron bombardment, especially in the case of a fusion reactor, is very difficult to shield againts. In fact, it is one of the mayor hurdles of fusion energy: the neutrons embrittle everything, including the superconducting magnets that contain the plasma.

Lithium and/or boron is an ideal shielding material, depending on what kind of reaction we are talking about. But they overheat, and not inpenetratable. One of the mayor hurdles for Tokamaks especially (like all IEC fusion fans, I take every chance to snap at the Tokamak programs I can get), is that due to its shape, all neutrons are absorded. And thus we end up with the situation when we have 500 Kelvin molten lithium next to 100 Kelvin superconductors. The Polywell design only takes away 5-10% of the neutrons, maybe more or less depending on what grid geometry we are using. However, we still have the mayor issue of cooling the grid, that too contains superconducters (or in the case of the possibly upcoming prototype, liquid nitrogen).

In the case of Polywell, for aircraft application, we will most likely be talking about a p-b11 fusion reactor with boron shielding (yes, we will use the same material for shielding as for fuel, no the shielding material will not become fuel material). Electricity generation will be direct, so there will be no need for turbines or generators.

While I see the logic, that might actually be a bad idea. If biofuels and/or hydrogen or whatever works off, then there should be an economical force to pressure it's development. The best way to fund a technology is to make it avalaible to the public. If there is public demand for it, then it will be developed further and more biofuel will be made.I think there should be a government mandate against the use of biofuels by owners of personal vehicles and instead towards to fufilling higher priority, essential, needs so that if the shit ever hits the fan there won't be an absolute collapse of infrastructure, of trucking, of agriculture and so forth.

If we cut off the option of biofuels/hydrogen/whatever away then the public will be stuck with the other option of regular oil. People have cars, and a deal of them need cars, and a good lot more of them DEMAND cars.

The idea of supporting mass transportaion more is a sane and logical one. However, it meets a dead stop at cultural imperative. People want cars, people need cars and cars need fuel. Politics will move towards this, whoever promises avalability of fuel to the public will get elected.

That said, public transportation, especially trains that are a simple yet still highly efficient, has to be developed. With some sanity, governments will try to do that as well as to balance fuel production.

Actually, I recall that by the end of it, they turned that drawback into a feature. The final plans involved an unmanned, constantly flying hell-machine that was a weird hybrid of a missle and a bomber. The radiactive pullotion was another weapon next to its sonic boom, that supposedly would have been strong enough to brake glass. I think. From what I gather, a single one of this little devils would have counted up what several ICBMs and then some.They obtained results, although the horrifying deadly radioactive exhaust was a persistent drawback to the design.

Neutrons can be shielded against nicely?

I was so surprised by this, after not finding anything convenient via google (it is/i] fast), I went upstairs to the ATLAS group and looked at their posters. One of the profs asked if he could help me, and I asked him, in either particle accelerator or fusion reactor context, whether neutrons were at all easy to stop, esp. in comparison to gammas.

The answer was exactly what I expected: Gammas are stopped pretty much immediately, even the insanely high energy ones they're looking at in a particle accelerator context (much higher energy than in a fusion reactor). Neutrons go a lot further. Another professor who overheard said that neutrons were the only thing (besides neutrinos) that gets out of fusion reactors at all.

And a flying fusion reactor is going to be lighter and less shielded than a ground-based one.

So there's going to be neutron radiation.

And neutron radiation is especially pernicious, since it makes many common kinds of matter itself radioactive. It's not just an issue of embrittlement.

And the Prof is very right. Neutron bombardment, especially in the case of a fusion reactor, is very difficult to shield againts. In fact, it is one of the mayor hurdles of fusion energy: the neutrons embrittle everything, including the superconducting magnets that contain the plasma.

Lithium and/or boron is an ideal shielding material, depending on what kind of reaction we are talking about. But they overheat, and not inpenetratable. One of the mayor hurdles for Tokamaks especially (like all IEC fusion fans, I take every chance to snap at the Tokamak programs I can get), is that due to its shape, all neutrons are absorded. And thus we end up with the situation when we have 500 Kelvin molten lithium next to 100 Kelvin superconductors. The Polywell design only takes away 5-10% of the neutrons, maybe more or less depending on what grid geometry we are using. However, we still have the mayor issue of cooling the grid, that too contains superconducters (or in the case of the possibly upcoming prototype, liquid nitrogen).

In the case of Polywell, for aircraft application, we will most likely be talking about a p-b11 fusion reactor with boron shielding (yes, we will use the same material for shielding as for fuel, no the shielding material will not become fuel material). Electricity generation will be direct, so there will be no need for turbines or generators.

Credo!

Chat with me on Skype if you want to talk about writing, ideas or if you want a test-reader! PM for address.

Chat with me on Skype if you want to talk about writing, ideas or if you want a test-reader! PM for address.

- Elfdart

- The Anti-Shep

- Posts: 10728

- Joined: 2004-04-28 11:32pm

I thought all that stuff was already used as low-cost fodder for livestock.Admiral Valdemar wrote:I always assume that cellulose sources would be from the wastes of agriculture, such as leaves, stems and thrown out foodstuffs. That way you're simply making the system more efficient, rather than, as we're doing now, drive up food prices to protest levels by chucking corn, soya and rapeseed into your fuel tank.

- Admiral Valdemar

- Outside Context Problem

- Posts: 31572

- Joined: 2002-07-04 07:17pm

- Location: UK

Not all of it. There's likely a great deal that still just goes to waste or gets composted (not that the latter is a bad idea anyway given soil erosion today on such scale).

If we recycled more of our organic wastes, we'd have a lot more power generating capacity if it was shipped to local power plants and used. Decentralized power grids are not the future and given the state of the US' infrastructure with well over a trillion needed just to bring it up to current spec, I think that's just as well.

If we recycled more of our organic wastes, we'd have a lot more power generating capacity if it was shipped to local power plants and used. Decentralized power grids are not the future and given the state of the US' infrastructure with well over a trillion needed just to bring it up to current spec, I think that's just as well.

- Sikon

- Jedi Knight

- Posts: 705

- Joined: 2006-10-08 01:22am

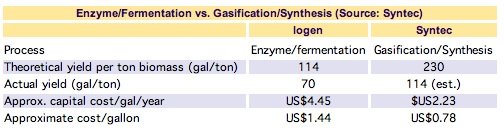

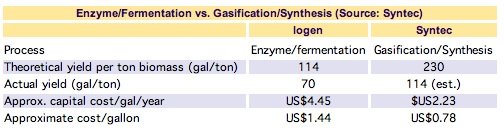

Adding a bit more to my previous post, especially quantitative information on actual costs:

Of course, vehicles have to be able to utilize the ethanol fuel, but most vehicles can run on a blend of mostly gasoline with some ethanol while many new vehicles can run on mostly ethanol. That's a lesser version of the situation in Brazil where most cars are flex-fuel and about 40% of gasoline consumption has been replaced with ethanol (from sugarcane, better than corn but with less potential than cellulosic ethanol).

As mentioned in the previous post, the Range Fuels cellulosic ethanol plant starting partial production next year is 0.1 billion gallon annual capacity, so the $76 million DOE grant is an effective subsidy of just $0.76 per gallon of annual capacity. The total cost is multiple times higher, but the majority of funding is the private investment of the company, counting on prices low enough to make a profit in the marketplace (with the help of the moderate government support).

Here's another example, for Iogen's plant:

The $2.25 cost per gallon of cellulosic ethanol is closer to $3 per gallon of gasoline equivalent, considering the mileage per gallon difference as mentioned earlier.

Cutting production costs drastically may seem optimistic, but it is not necessarily excessively so. An analogy is the cost history of non-cellulosic ethanol production, where technological refinement dropped plant costs from around $2.07 per annual gallon in 1978 to between $1.25 and $1.50 per annual gallon after a couple decades later.

Even the current economics of cellulosic ethanol aren't too bad if placed in perspective by comparing to European gas prices after taxation, which can be high figures such as $8 per gallon.

And there's the potential future cost decrease, e.g.:

Although mainly about other biofuel production, the following is still of some relevance, illustrating factors talked about such as higher oil prices increasing interest in alternatives:

In general, although cellulosic ethanol and other biofuels aren't going to replace much of a percentage of total oil imports overnight, they have significant, interesting potential over the next decade to be of some assistance.

From here.Corn ethanol delivers 20 to 50 percent more energy than it takes to produce, and cellulosic up to 600 percent more.32

[...]

Producing corn ethanol in the U.S. currently costs about $1.50 to $1.60 per gallon, but it is produced for significantly less elsewhere. In an article from fall 2005, the Rocky Mountain Institute pointed out that Brazilian ethanol was selling in New York for $1.10 a gallon, despite an import tariff of 54 cents a gallon.34 Producing cellulosic ethanol – a new technology just beginning to develop its potential – costs more than producing ethanol from corn. However, the cost to produce cellulosic ethanol will go down as the industry implements new technologies and efficiencies.

[...]

It’s true that ethanol contains less energy [per gallon] than gasoline, but for vehicles using E10, the lower energy content of ethanol does not adversely affect fuel efficiency. E85-fueled cars experience about a 17 to 25 percent decrease in mileage, depending on speed and terrain [making a gallon of ethanol equivalent to around 0.8 gallons of gasoline in mileage].

Of course, vehicles have to be able to utilize the ethanol fuel, but most vehicles can run on a blend of mostly gasoline with some ethanol while many new vehicles can run on mostly ethanol. That's a lesser version of the situation in Brazil where most cars are flex-fuel and about 40% of gasoline consumption has been replaced with ethanol (from sugarcane, better than corn but with less potential than cellulosic ethanol).

From here.Manufacturing flex-fuel vehicles is a trivial change [...] It costs less than $200 per vehicle.

From here.In late February, the U.S. Department of Energy (DOE) awarded grants totaling $385 million to six firms with plans to develop and commercialize the production of cellulosic ethanol. Range Fuels was one of the companies recognized by the DOE for its promising cellulosic ethanol technology and was selected for a potential $76 million grant for its first cellulosic ethanol plant to be built at a site near Soperton, Georgia.

As mentioned in the previous post, the Range Fuels cellulosic ethanol plant starting partial production next year is 0.1 billion gallon annual capacity, so the $76 million DOE grant is an effective subsidy of just $0.76 per gallon of annual capacity. The total cost is multiple times higher, but the majority of funding is the private investment of the company, counting on prices low enough to make a profit in the marketplace (with the help of the moderate government support).

Here's another example, for Iogen's plant:

From here.A June 2006 U.S. Senate hearing was told that the current cost of producing cellulosic ethanol is $2.25 per gallon, which is not competitive [except with governmental support] when distribution costs are added. The DOE is asking for more research funding, however, and has a target to cut the cost of production in half by 2012.

The $2.25 cost per gallon of cellulosic ethanol is closer to $3 per gallon of gasoline equivalent, considering the mileage per gallon difference as mentioned earlier.

Cutting production costs drastically may seem optimistic, but it is not necessarily excessively so. An analogy is the cost history of non-cellulosic ethanol production, where technological refinement dropped plant costs from around $2.07 per annual gallon in 1978 to between $1.25 and $1.50 per annual gallon after a couple decades later.

Even the current economics of cellulosic ethanol aren't too bad if placed in perspective by comparing to European gas prices after taxation, which can be high figures such as $8 per gallon.

And there's the potential future cost decrease, e.g.:

From here.BC International is applying a proprietary acid hydrolysis technology to agricultural residues and forest thinning feedstocks to produce ethanol. The company is developing facilities in Louisiana, California and Asia and claims their process produces ethanol at costs lower than conventional ethanol plants. Arkenol and Masada Corporation (mentioned earlier) are also developing biorefineries in the U.S. utilizing acid hydrolysis process to convert cellulosic wastes into ethanol. A Japanese company, licensing Arkenol's acid hydrolysis technology, is already producing ethanol in a plant in Izumi, Japan from [cellulosic] waste.

Although mainly about other biofuel production, the following is still of some relevance, illustrating factors talked about such as higher oil prices increasing interest in alternatives:

From here.U.S. Senate Committee on Environment & Public Works

Date: 09/06/2006

[...]

In 2000, 1.6 billion gallons of ethanol were produced in the United States. By 2005, 4 billion gallons of ethanol were produced, a 150-percent increase in 5 years. In 2006, nearly 5 billion gallons of ethanol are expected to be produced, a one-year increase of 20 percent. Today, over 100 ethanol plants operate in 20 states. The Renewable Fuels Association reports 42 ethanol plants are under construction and another 7 are expanding. When that construction and expansion is completed, ethanol capacity in the United States will be 7.7 billion gallons per year.

[...]

The surge in oil prices has made biofuels much more cost competitive with gasoline, helping to spur new investment.

[...]

Further, if the world price of crude oil remains higher than $50 (in 2005 dollars) per barrel in the future, as projected by EIA, and corn prices do not rise considerably, then ethanol would be used as a gasoline extender, because ethanol would be competitive with gasoline and demand for ethanol would readily exceed the minimum levels in the RFS. Below about $30 per barrel for crude oil, there would no incentive to produce corn ethanol beyond the RFS, because ethanol would be unprofitable to produce and market as a fuel extender.

[....]

U.S. biodiesel production remained very small and flat until USDA created the Commodity Credit Corporation Bioenergy Program in fiscal year (FY) 2000 that encouraged biodiesel production through cash payments to producers. Mostly as a result of this program, biodiesel production jumped from 500,000 gallons in 1999 to 28 million gallons in 2004. In 2005, 91 million gallons of biodiesel were produced with 65 million supported by the program. The Bioenergy Program authorization from the 2002 Farm Bill ends in FY 2006. Even so, with high diesel prices and new tax incentives, USDA forecasts biodiesel production will reach 245 million gallons in 2006, a 170-percent increase year over year and a 490-fold increase since 1999.

As of April 2006, the National Biodiesel Board indicated there were 65 commercial U.S. biodiesel plants. The annual production capacity of these plants ranges from 200,000 gallons to 30 million gallons, and they have a total capacity of about 400 million gallons.

[...]

The National Biodiesel Board reports that there were 50 new plants under construction as of April 2006 that are expected to add another 700 million gallons to annual capacity.

[...]

Adding the expected return to investment and the costs for transportation, blending, and marketing would push the expected retail price of 100 percent biodiesel (B100) well over $3.00 per gallon. Until recently, the high cost of biodiesel has made it very difficult for biodiesel to compete in the diesel fuel market. However, with the recent surge in crude oil prices, diesel fuel prices have risen to historical highs, and biodiesel has become more cost competitive. Moreover, recent legislation has granted biodiesel a $1.00 per gallon excise tax credit and a $0.10 gallon small producer tax credit. Government incentives along with higher diesel fuel prices have made biodiesel production profitable and the industry is now expanding rapidly, much like ethanol. Biodiesel production is expected to continue growing rapidly over the next few years, with over 100 plants expected to be on-line by the end of 2007.

In general, although cellulosic ethanol and other biofuels aren't going to replace much of a percentage of total oil imports overnight, they have significant, interesting potential over the next decade to be of some assistance.