NASA calculated in 1962 using the then-level of fatalities and commercial availability that in order for space travel to be as common as air travel, you needed:

LOW EARTH ORBIT:

50 x Flights a Year, each with 50 passengers, with one un-successful flight.

LUNAR TRAVEL

25 x Flights a Year, each with 10 passengers, with one un-successful flight.

Costs required to make this happen would have been:

$5/lb to LEO in 1962 Dollars. ($40/lb in 2011 Dollars)

$25/lb to Moon in 1962 Dollars ($190/lb in 2011 Dollars)

Later in mid 1970 at a speech at the University of Michigan, Lockheed's Max Hunter mentioned that if costs per pound went below $50/lb ($285 in 2011), then Texas Instruments would do manufacturing in space. He also mentioned that if costs went below $5/lb ($28.5/lb in 2011), then it would become feasible for Hilton to build space hotels.

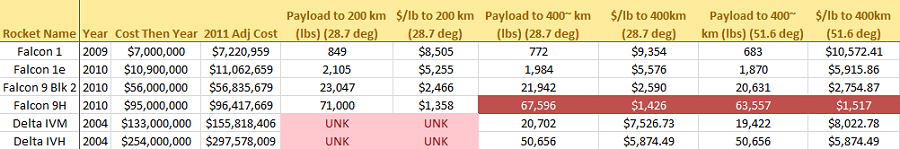

Right now, it's pretty hard to figure out launch costs, since little if any actual costing data is released by the companies involved in the business (all proprietary trade information, natch).

But there are a few datapoints:

SpaceX in order to attract people to their SLVs has to release public data, and until 2004, Boeing/ULA was selling Delta IV commercially, and had to release public data.

I've collated the datapoints into this table using information found in:

Falcon 1 User's Guide

Falcon 9 User's Guide

Delta IV Payload Planners Guide - September 2007

Red Background is extrapolated data based off Falcon 9 performance reduction as you go higher.

To help you understand this a bit better, here's some explanation of the orbits -- Low Earth Orbit (LEO) is not monolithic.

200 km @ 28.7 degrees: Basically Gemini/Mercury manned flights. You stay up there for a couple weeks. Air drag is still a significant influence (relatively).

400 km @ 28.7 degrees: High altitude LEO. Stay there for years (with appropriate yearly reboosts). Not reachable by Russia directly due to poor geographic location.

400 km @ 51.6 degrees: High altitude LEO. Stay there for years (with appropriate yearly reboosts). Reachable by Russia. Currently used for ISS, previously used for Salyut, Mir and Skylab (50 deg).

Ok, onto our next point:

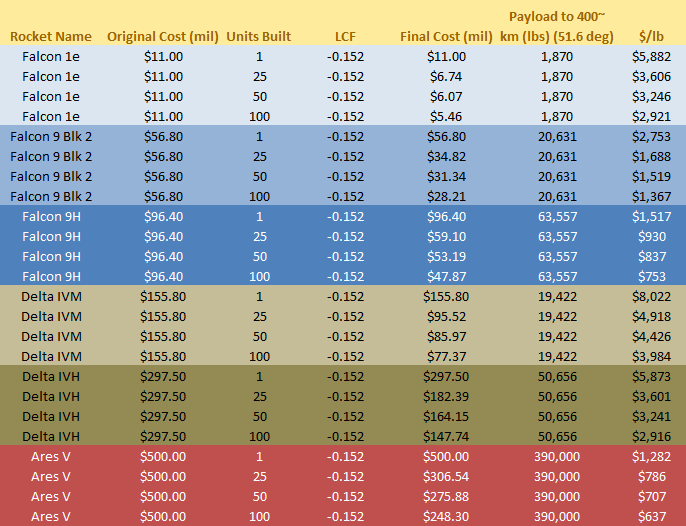

One of the most common refrains used as a way to lower launch costs is to build the vehicles en-masse, and lower costs via mass production.

Brief Description of Production Cost Curves by Me

In August 1965 at the Conference on the Exploration of Mars and Venus at the Virginia Polytechnic Institute they put together costs for a 1975 Manned Venus Flyby and a 1978 Manned Mars Flyby using the following assumptions:

Saturn V: 90 percent learning curve, 62 prior units built; $70 million unit cost.

Saturn IB: 90 percent learning curve, 52 prior units built, $22 million unit cost.

Apollo CSM: 95 percent learning curve, 70 prior units built, $72 million unit cost.

This gives us an idea of what kind of PCC/LCC we can realistically expect from SPACE [tm].

Here are the final computed prices for Falcon 1e/9/Delta IVM/IVH using a PCC/LCC of 90%:

As you can see, mass production can reduce the cost of sending something into LEO by up to 50%. But it still remains a steep wall to be climbed.

I honestly don't think that mass production of space launch vehicles past the range of 50-100 launchers to a Block will ever happen.

For one, by the time you hit that range of production, you would be ready to move onto the next Block, requiring a lot of retooling.

Finally, each individual flight would see little increments of improvement creep in until rocket #56 off the production line has so many differences that it can't credibly be compared to rocket #3.

If you wanted to lower launch costs to maybe $700 a pound for Falcon 9, you would have to produce 8,200 of them to the same basic design with a LCC/PCC of 90%.

That clearly isn't happening. Not unless we suddenly discover we have to build a moonbase in five years to fight aliens on the moon to save the earth in Space War I.

So let's get into costing this per individual seat.

SpaceX's Dragon capsule will likely weigh about 18,000 pounds when it's in the 7 person configuration. That's about $30 million dollars roughly to launch it with the 50th Falcon 9 off the production line.

Figure a basic cost of $30 million for a Dragon Capsule, and that it flies for ten flights before retirement, and you have about $5 million basic cost per flight for the capsule (recovery, refurbishment, and allocating for replacement added into basic cost).

With six paying passengers, that comes out to about $5.83 million per passenger. That's almost nine times less than what Russia is charging for a Soyuz flight right now as of 2011 ($52~ million USD).

Even if SpaceX manages to develop a larger 12-person capsule, the seat prices only drop to $3.18 million. ($30m basic launch cost + $5m capsule amortized cost)

Clearly, we are not going to get the price down to what the average person is willing to pay with expendable launch systems.

If we took something conceptually similar to Max Faget's DC-3 Concept:

Essentially, it's a vertically launched, horizontally landing fully reusable system. There's a very good reason for vertical launch. The heaviest plane in the world right now is the An-225 with a 650 tonne MTOW. A lot of TSTO concepts are in the range of 2,000+ tonnes.

That's a lot of weight the landing gear and structure have to take when it taxis to takeoff. By contrast, launching like a rocket means you can size the landing gear for it's empty weight, saving a lot of weight and money.

The first stage (booster), would have weighed 1,600 tonnes fully loaded and 273 tonnes dry, for a propellant loading of 1,327 tonnes. It would have been powered by no less than 10-12 SSMEs, and landed with the assistance of four jet engines at a conventional runway.

The orbiter would have weighed 395 tonnes fully loaded and 121.5 tonnes dry, for a propellant loading of 273.5 tonnes. Power would have been through two SSMEs. It would have had four jet engines for conventional runway landing. Crossrange would have been 200+ miles. By contrast Orion will have about 100 miles, and the Shuttle 1,200~ miles.

Crew would have been 2, with ten passengers somewhere in there.

The payload bay of the orbiter would have been 8 x 30 feet (versus Shuttle's 15 x 60 ft bay); and the complete system would have carried 15,000 lbs into a 498 km high orbit with an inclination of 55 degrees.

There were several reasons why the DC-3 concept died.

- The USAF demanded 1,200 mile crossrange, so orbiters on a polar orbit could land at Vandenberg AFB when they were brought into the program to "spread costs". DC-3 only had 200~ mile CR.

- Fully-Reusable was expensive. They were looking at easily $9.9 to $7.7 billion for R&D for that, compared to $6.4 billion for a partially reusable. It went even lower to like $5B cost for the shuttle configuration we know and sort of like.

- The DC-3 used titanium. At the time, only a few closed machine shops working on classified military programs had experience in making stuff on a big scale (SR-71). If it was aluminium, the whole aerospace industry could work on STS. This was why USAF preferred aluminum.

- Von Braun and his MSFC team were dubious of the viability at present (1970) technological levels of a large cryogenic tank system that could repeatedly be chillled/warmed and pressed for a semi-expendable system.

Assuming the orbiter/booster each cost $1.25 billion each and fly 100 missions before replacement, that's about $30 million cost per flight for the hardware. Maybe $50 million every 25th flight as it gets overhauled.

Propellant costs in a fully reusable system would quickly dominate:

LOX: $198.41/tonne (2001)

RP-1: $1,235/tonne (2010)

RP-1: $2,435/tonne (If gas prices hit $7.50)

LH2: $5,490/tonne (2010)

PBAN: $10,846/tonne (Derived from $2.50/lb in 1985 for PBAN with 4mlb production/yr).

A full tank-up of a DC-3 would cost about $8.7 million.

(Yes, I know you would have a lot of LOX, bringing the price down; but lets assume that it's 100% LH2 to provide a margin of cost safety.)

We'll assume for simplicity that total launch costs are $45m to be on the really safe side budgetwise.

An 8 x 15 ft cargo bay can accomodate about five rows of airliner seats in a 2+1 configuration, giving you a 15 passenger module. Add that to the 10 guys up front in the orbiter, and you have 25 passengers paying about $1.8 million a seat.

If you went with a non-traditional seating system, in which people stood up (remember that during launch, they will be on their backs, and while they wait for re-entry, they'll be in mostly zero gee); you could get a lot more people in; maybe about 45. That drives prices down to $1m.

If you went for a passenger-only shuttle, eliminating the cargo bay and making one long passenger compartment, you could get even more people in. Probably about 65. Prices go down to $690k.

At this point fundamentally, the best we can get things down to with a rocket based TSTO system is about $150-200k per seat. That's if we assume a near-totally depreciated asset in which the only reoccurring cost is filling up the fuel tank(s) and the parts installed will last until retirement.

That's more than enough to get a space-based economy going. The US military already pays the equivalent of about $100k for a soldier's gear these days, and companies would be willing to pay $300k to send someone up into orbit to spend a year or two working at a space based research laboratory.

But it's still far below what the average person is willing to pay.

Some historical comparisons of airline tickets:

1940: Delta Airlines Atlanta-Fort Worth on DC-3: $38.50 ($608.60 in FY11)

1960s: Cleveland-Washington DC: $75 ($526.93 in FY11)

2011: Dulles to Toyko with 1.5 months' warning: $1,000~

For the common man, the best seat price he could realistically afford would be about $4 grand.

Alienware makes money selling $3,999 desktops to the performance market. I'd imagine a flight to space would be in even more demand than street cred at gaming conventions.

When LH2 scramjets with an ISP of about 1,250 become practical to about Mach 6 or 7, it means that our first stage booster that weighs 1,650 tonnes suddenly shrinks to only about 350 tonnes.

Likewise, by then large LH2 engines with an ISP of about 460 will be around, meaning that the orbiter can shrink a little.

All this would end up with a system capable of offering seats to orbit for about $70-80k when totally depreciated.

Eventually as scramjets become more advanced, each one going higher and faster than the previous generation; we can push staging faster and higher.

Instead of having to stage at Mach 6, we can wait to stage until Mach 8+ or more, and spend more time running on scramjet power before we switch to rocket power for the last push to orbit.

At some point, we'll know enough to integrate our scramjets with a rocket engine to create a RBCC (rocket based combined cycle) system that weighs less than having both engine types on the launcher, making some sort of SSTO feasible, saving a lot of money on operating costs.

By this point, there would be enough of a market for aerospace companies to seriously propose building large spaceplanes that could carry upwards of 300 or more people into orbit, allowing for space travel to undergo the same revolution that happened when 747s and other widebodies began to appear from 1967 onwards.

The biggest cost would be involved in getting out of earth's gravity well. Once you were docked at the Alan B. Shepard Orbital Hub, you would only spend a couple hundred more to go to Armstrong City on the moon.

-----------------

One last thing before I sign off:

At the flight cost of $25 million that STS was supposed to have during the planning phase, these 72 peeps would be paying only $347k.

Even if we went with the current $500m per STS launch of today, the cost per passenger would be $6.9 million, beating out SpaceX and the Russians.