Page 14 of 18

Re: Housebuilding in Finland

Posted: 2015-12-12 03:45pm

by His Divine Shadow

Fitted a slower (1400rpm) motor to my lathe now:

I still need to get a step pulley for the motor to get more speeds but this is still slower so a big improvement. And cut off the excess amount of rod and paint the thing a matching color I think. Used it tonight to turn a piece of oak into a french rolling pin, figure I'll give it away as a christmas gift to someone.

Still needs some work, the marks on the edges are just so I know where to cut off the ends later.

Re: Housebuilding in Finland

Posted: 2015-12-16 01:30am

by His Divine Shadow

Rolling pin finished:

Also another cutting board, will also be a present. Still soaking in the linseed oil:

Shallow feet in a sliding dovetail:

Also need to get started on a photo frame. I wanted to make a frame from birch or ash and join it with walnut dovetail butterfly keys that would stand proud of the frame itself. But I'm not sure it won't be too difficult. I can't get them cut with my router table in a precise enough way so I'd have to make them by hand. I feel like I need to invest in some better bits too, only got the shitty cheapest ones.

Re: Housebuilding in Finland

Posted: 2015-12-16 01:59am

by Jub

I think I liked the rolling pin better with the grooves on each end, they gave it a touch of style.

Otherwise, your work is amazing. I wish I had the kind of drive in me to create the way you do.

Re: Housebuilding in Finland

Posted: 2015-12-23 02:19am

by His Divine Shadow

Thanks, I also tried my hand at making a picture frame with my kids in it. Harder than I thought, the sliding dovetail was easier. Those mitres are such a PITA.

Back's not so important but that's what it looks like. Material is ash, the coloration is due to sapwood and heartwood meeting.

Re: Housebuilding in Finland

Posted: 2015-12-23 11:26am

by Elheru Aran

For mitre work, I understand a 45-degree shooting board can be a real godsend...

Re: Housebuilding in Finland

Posted: 2015-12-26 07:18am

by His Divine Shadow

I've been looking at shooting boards though I am hesitant, not sure I can make it accurately enough... There are miter jigs like the one made by steve ramsey that seems pretty foolproof.

Re: Housebuilding in Finland

Posted: 2015-12-26 03:27pm

by His Divine Shadow

Made a disk sander attachment for the lathe today, with that I tried shaping some wood into a tape roll holder. I think it's cute, much nicer than those plasticky crappy things you get in stores:

Re: Housebuilding in Finland

Posted: 2015-12-26 10:56pm

by LadyTevar

That's adorable!

Re: Housebuilding in Finland

Posted: 2016-01-10 01:13pm

by His Divine Shadow

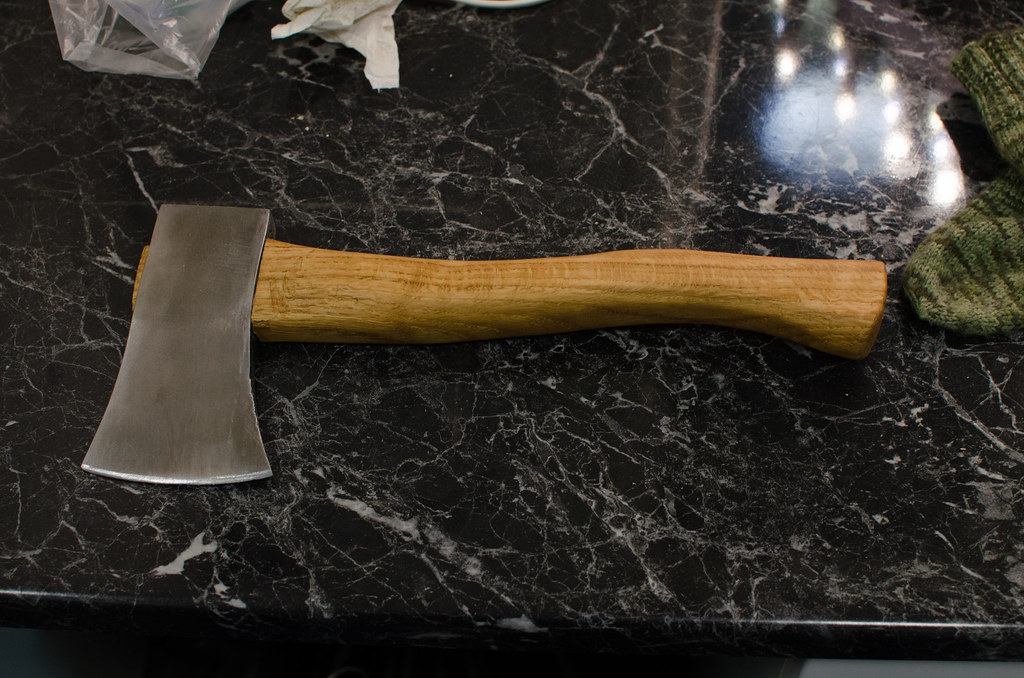

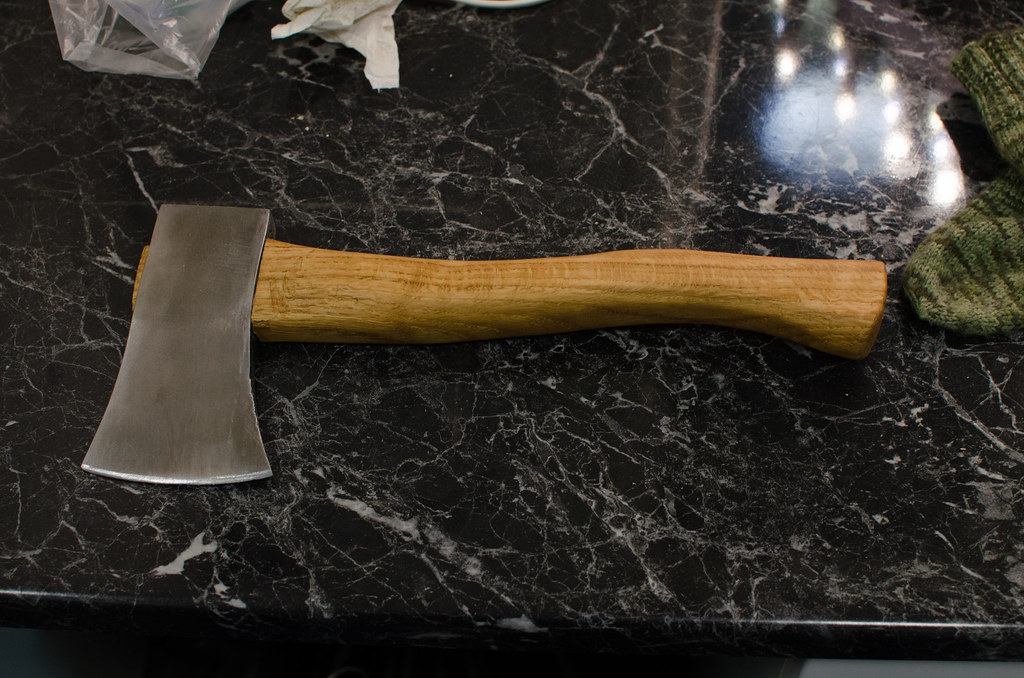

Thanks, been real cold here recently, down to -30C here. Fortunately the house just gets warmer the colder it gets. I feel more warm now than I've done when it was +5C outside. The floor heating is really noticeable at these temps. The cat loves it. And been going through the firewood too, that made me realize I need an axe to make kindling as my big splitting maul isn't suited to it. So I got this axe head for 5 euros that I fitted a new oak shaft to, roughed it out on the bandsaw then it was mainly spokeshave and rasp work:

Also acquired a 165mm (6½") circular saw at the same place, 25 bucks and in good working condition (I had it taken apart and gone over):

Re: Housebuilding in Finland

Posted: 2016-01-10 02:04pm

by Borgholio

So I got this axe head for 5 euros that I fitted a new oak shaft to, roughed it out on the bandsaw then it was mainly spokeshave and rasp work:

Mind if I axe how long it took you to make it?

Re: Housebuilding in Finland

Posted: 2016-01-10 02:07pm

by His Divine Shadow

Heh... I think it took 3-4 hours.

Re: Housebuilding in Finland

Posted: 2016-01-10 10:23pm

by fnord

Nice work on the axe - and that kitchen countertop makes a great photographic background for it, too.

Re: Housebuilding in Finland

Posted: 2016-01-10 10:29pm

by Jub

Seeing all this and the deals you're getting on your tools, I'm tempted to pick up a few basic woodworking tools when I move into someplace with a suitable work space.

Re: Housebuilding in Finland

Posted: 2016-01-11 05:04am

by LaCroix

3-4 hours for a handle is long. I know it takes that long doing it properly by hand, but I'd propose you build yourself a nice belt grinder.

Like that one, only with one of the lenghts supported by a backrest to make it stifff and flat (and leave the others 'sagging', for detail work).

The various diameter radii wheels are also very helpful

These things are a gift from the gods! Especially for making knife grips or things like that.

Re: Housebuilding in Finland

Posted: 2016-01-11 05:22am

by His Divine Shadow

I wanted to do it by hand though, it's relaxing and rewarding to get things done with just a rasp and a spokeshave.

A 2x72 grinder is a future project for metalwork though, but I have two other grinders I am building first. I am already halfway into building a 50x800mm slow belt sander for sharpening tools. Then a 150x1220mm one for shaping wood. I already have a 225mm (9") disc sander by putting an attachment on my lathe.

Re: Housebuilding in Finland

Posted: 2016-01-11 04:33pm

by His Divine Shadow

Jub wrote:Seeing all this and the deals you're getting on your tools, I'm tempted to pick up a few basic woodworking tools when I move into someplace with a suitable work space.

I always swing by certain places with regular intervalls and I also regularly check the craigslist equivalent. I simply couldn't afford the 200-ish euros a good saw would cost so waiting for a suitable one was the only way to go. I have been looking for 6-7 months before i stumbled on this. I also found a swiss made ELU circular saw but it was too heavy and clumsy I thought.

Re: Housebuilding in Finland

Posted: 2016-01-16 06:32pm

by Elheru Aran

EBay has been a godsend for buying tools for me here in the US. Not sure how useful it would be in Europe, regrettably.

Re: Housebuilding in Finland

Posted: 2016-01-19 04:52pm

by His Divine Shadow

It's useful for people in the UK and germany when it comes to bigger stuff, I thrawl a particular site the most as lots of locals put ads there. Distance is quite important so I can check things out in person.

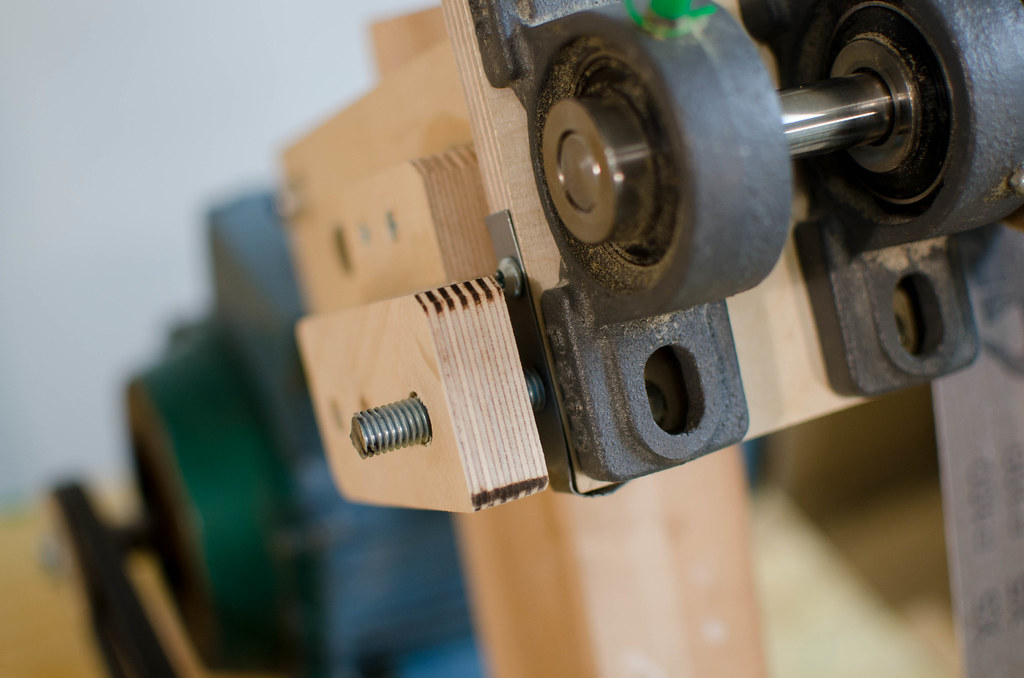

In other news I made the screw advance box joint jig by Matthias Wandel:

Instead of a guide bar I have it bolted to the sliding table. I put threaded inserts in the table that line up with the jig, so it'll always clamp down in the same place.

Re: Housebuilding in Finland

Posted: 2016-01-30 04:17pm

by His Divine Shadow

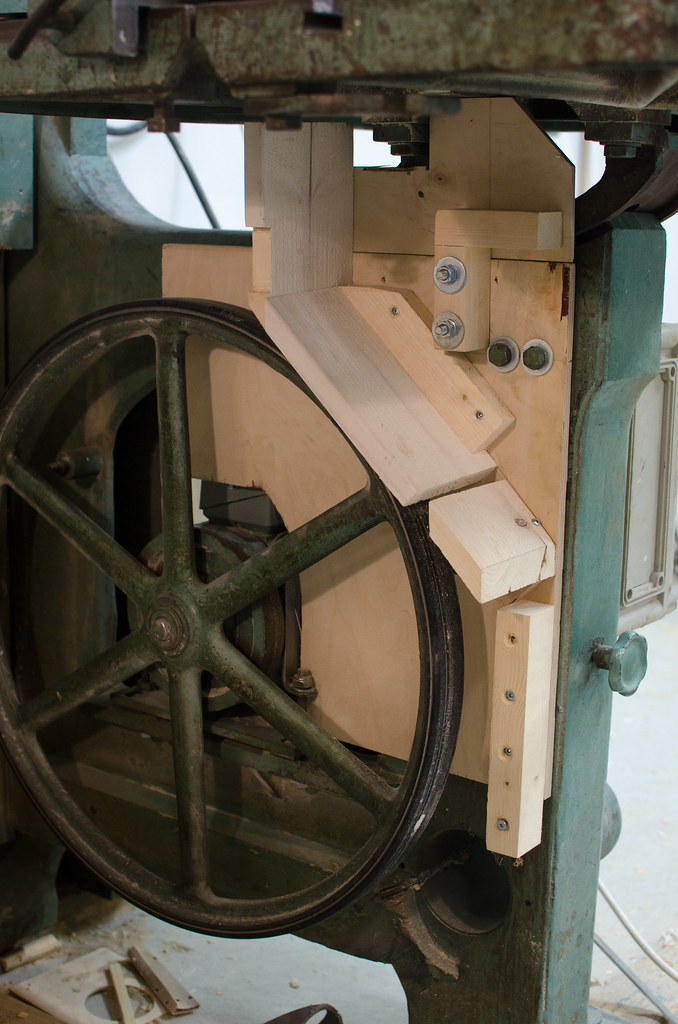

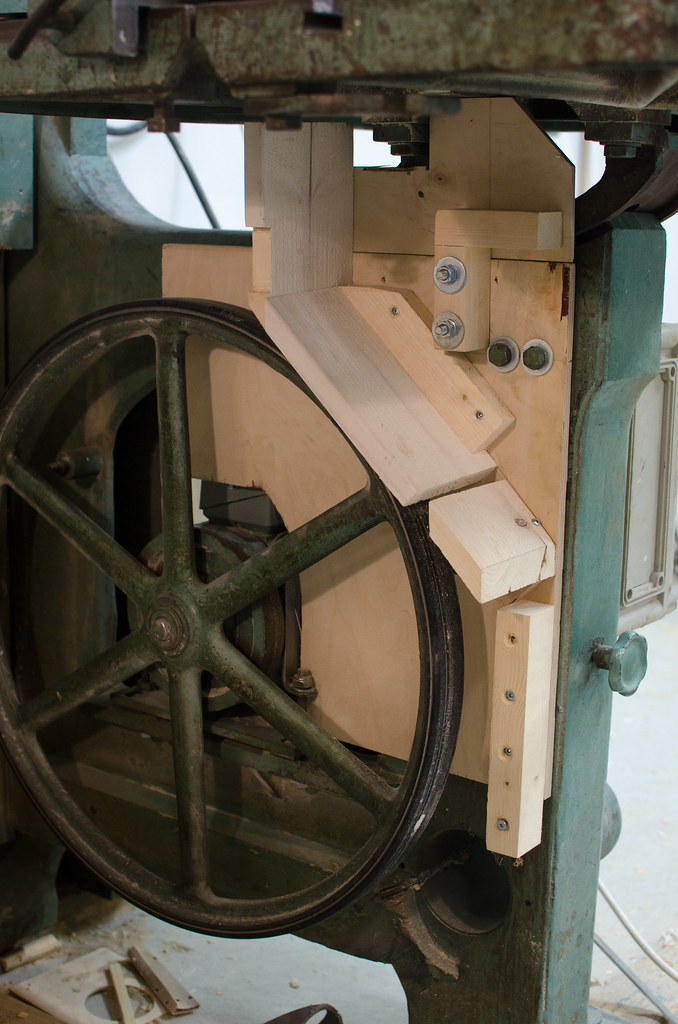

Rebuilt the lower blades guides for my bandsaw. These are the old ones, extremely simple, no thrust bearing, situated very far down under the table: Tracking hasn't been the best due to this.

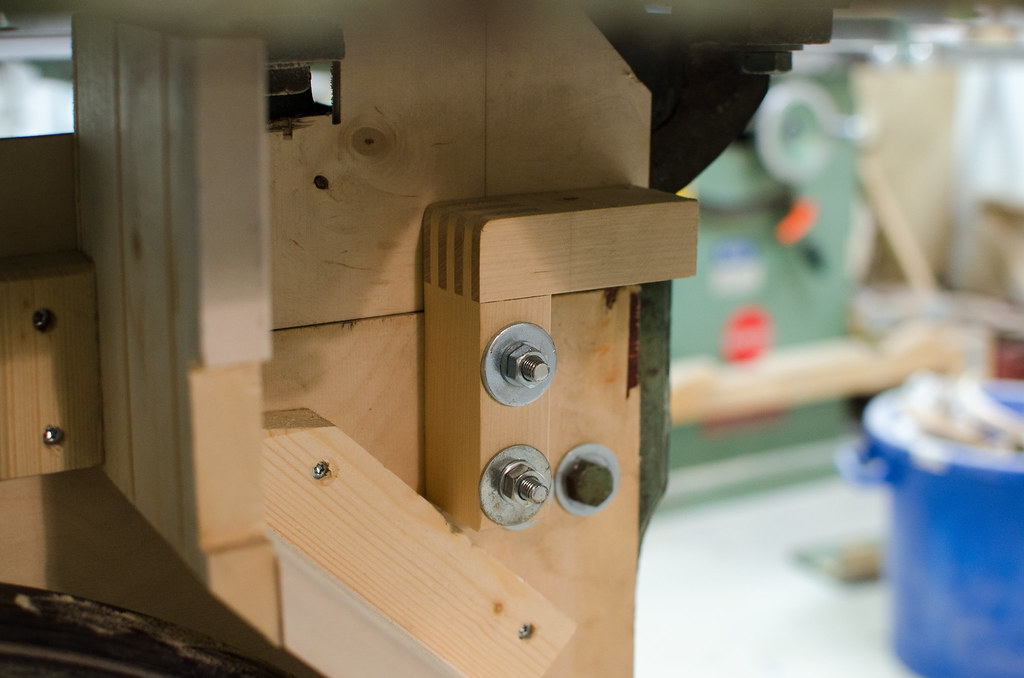

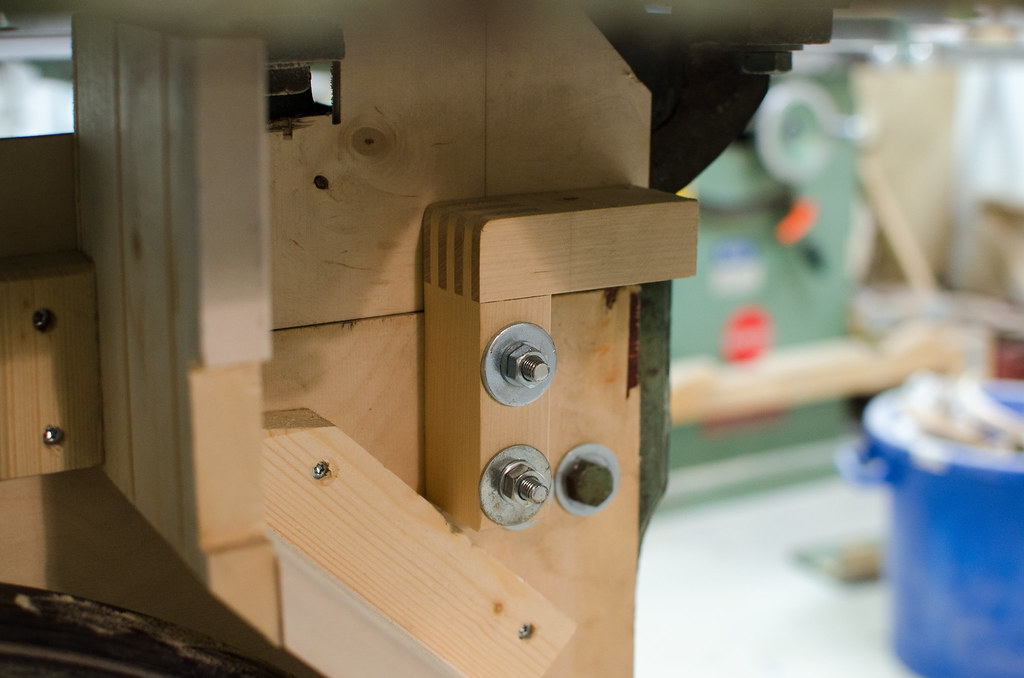

These are the new guides, made from scrap pieces of hardwood, oak side guides and a thrust bearing, I am very frugal with my hardwood so I've glued smaller pieces together to make a bigger whole:

The thrust bearing doesn't really have any adjustment, it's adjusted with the side bearings as one unit. But it doesn't really need any, for now. I'll have to see how it acts with other types of blades in the future. But I only have the one 1/2" blade.

In redoing the guides I am also redoing the dust collection system and closing in the underside of the table. The old system was simple and effective, but couldn't be used with the table tilted and also interfered with having the guides higher up. The spokes on the wheels act as fans which throw dust around, so enclosing the dust from the table like this solves a big problem with the original design. Where the two green bolts are, that's where the old guides sat.

The L-shaped piece of wood is the new mount for the guides, the box-joint jig is really handy for making super sturdy joins, box joints are the strongest join there is, stronger than dovetails:

A lag bolt fits into the slot on the guide body, see the slot in the back of the guides in the picture above,

Blade installed:

I believe if I wanted to, I could modify this design to use bearings as side guides, by mounting the bearings on cams that I would lock down instead of the oak blocks. But I think wooden blocks given good enough wood, are just as good as bearing guides. The difference in tracking is very noticeable to me. The saw cuts straighter and more accurately than before. I might remake them in metal sometime in the future. But wood seems to work well enough for now.

Work on enclosing the whole thing continues still.

Re: Housebuilding in Finland

Posted: 2016-02-07 12:17am

by Enigma

May sound stupid but I had to ask, do the bearing guide spin as the blade goes by? Does the guide actually touch that wooden block that its bolted to?

Re: Housebuilding in Finland

Posted: 2016-02-07 03:03am

by His Divine Shadow

The bearing is placed just so it doesn't spin, I tried to get is as close as I possibly could on that. The wooden blocks I've oiled in and those I put against the blade,

Also the box joint jig is stupidly precise, I made these two parts separately, rewinding the jig each time:

Re: Housebuilding in Finland

Posted: 2016-02-07 11:23am

by LadyTevar

That's a tight join! Fantastic

Re: Housebuilding in Finland

Posted: 2016-02-10 03:56am

by His Divine Shadow

Thanks, it's been a very useful addition to my shop, it makes all kinds of durable construction possible.

Kids are getting really handy with an ipad, can navigate programs and watch youtube on their own:

Came up with a method to attach the DC hose in a quick and easy way using these cheap clamps:

Still under construction, need to close in the open area under the table still.

Re: Housebuilding in Finland

Posted: 2016-02-29 06:20am

by His Divine Shadow

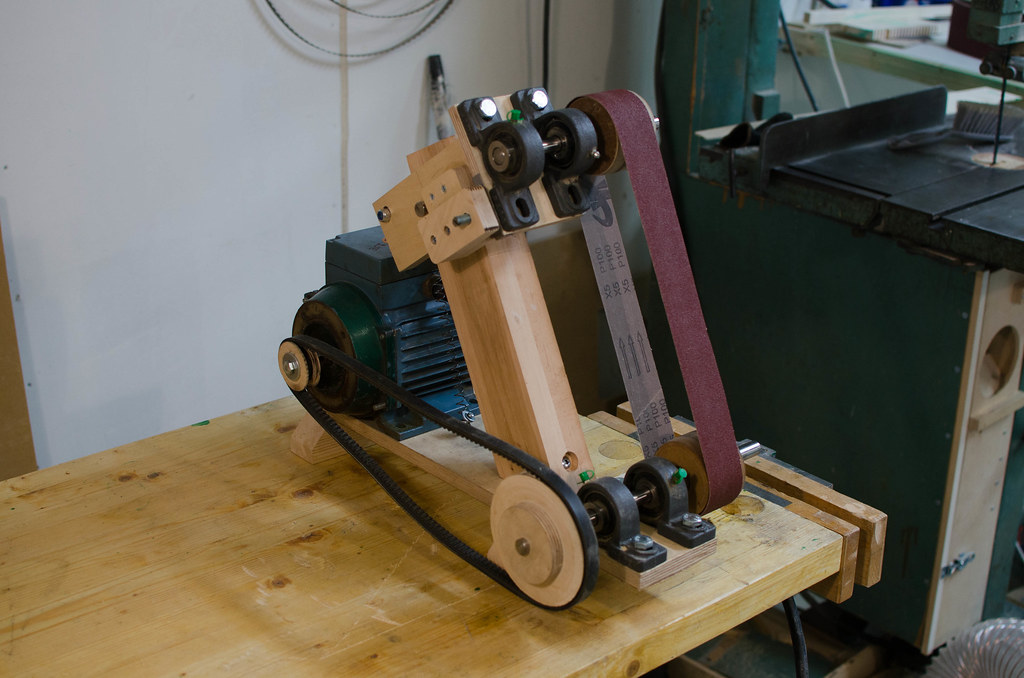

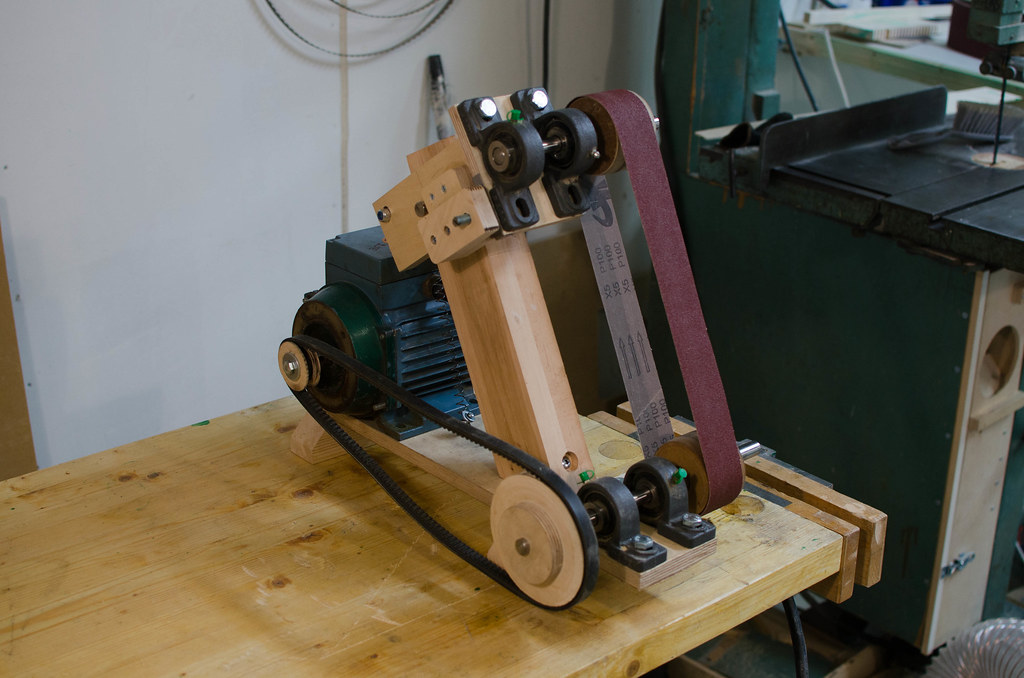

Work in progress, 2" belt sander for sharpening tools and knives

I plan to use it with sorby pro-edge belts (50x780mm or 2x30½") but the sander can take a pretty large variation in belt sizes, no problems taking a 915mm / 36" belt.

1HP 3phase motor, it's too fast so I am going to make as small a pulley as I can for the motor.

Re: Housebuilding in Finland

Posted: 2016-03-01 01:35am

by His Divine Shadow

Split the belt in half, cheap source of belts to use 4x36" ones and split them. Even more expensive quality 4x36" belts such as zirconia and ceramics are cheaper than the Sorby belts I was looking at when I factor in I get two belts from one.

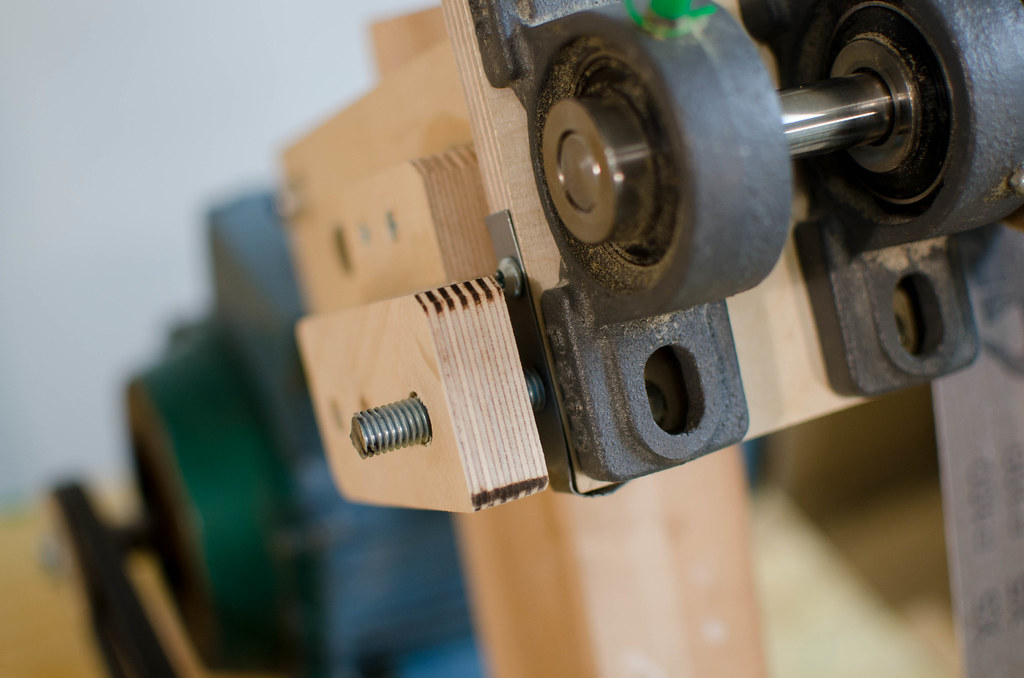

Here's how the tracking works, basically the upper portion tilts on a shaft to provide tension, then there is the plate with the bearing housings mounted to that, and said plate can rotate around it's center, without the screw the whole thing would just rotate down when pressure was applied:

Belt tension provided by an old spring from a 1911, it's not enough, this will be redone entirely:

I still need to make a platen and an adjustable table so I can hold tools at the exact angle against them. A bigger front pulley will slow the belt down and increase the belt tension (not enough ATM)